Recent safety incidents in high-rise buildings in cities have sparked public concern and discussion about the protective capabilities of residential spaces. As an emerging trend in the construction industry, how resilient are prefabricated buildings in terms of structure, materials, and construction?

With 12 years of experience in the tent construction industry, Jumei has provided the answer with its standardized, high-precision, and highly controllable product implementation standards: a truly luxurious outdoor experience is built on an uncompromising foundation of architectural-grade safety.

▲Zhejiang Reclamation Culture Park Project

Multiple active protections to build a solid safety barrier

▼Material-level source protection

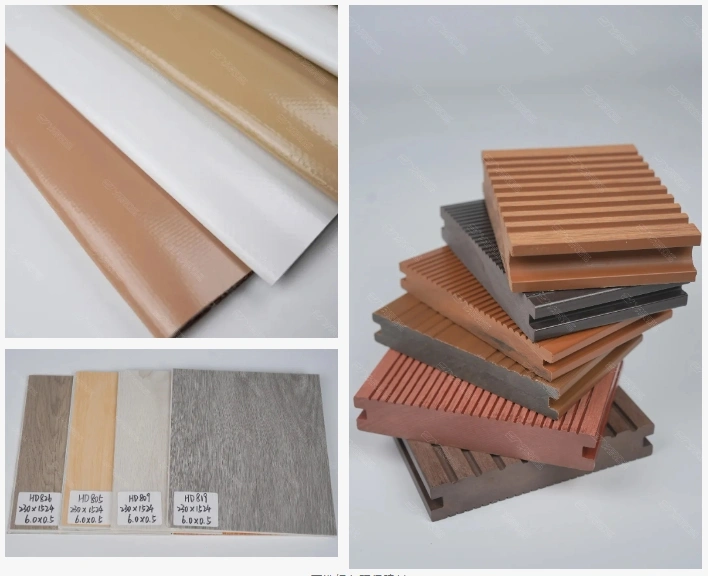

From tarpaulins to boards, we strictly control the non-toxic and harmless standards of raw materials, and use new environmentally friendly materials such as PVDF architectural membrane, SPC waterproof flooring, and WPC outdoor wood flooring, which have the characteristics of waterproof and moisture-proof, heat insulation, corrosion resistance and aging resistance.

▲ Carefully selected green and environmentally friendly building materials

The material meets the national standard B1 flame retardant rating (flame-retardant material), has good flame retardant properties, and does not contain toxic substances such as formaldehyde, benzene, and asbestos. It is difficult to ignite when exposed to open flames or high temperatures in the air, does not easily spread, and can self-extinguish within a short time after being removed from the fire source, without continuing to burn or producing large amounts of smoke and toxic gases.

▲Flame retardancy tests on various tarpaulins such as PVDF, PVC, and canvas

It also excels in waterproof performance. The tarpaulin used by Jumei remained completely waterproof even after continuous water spraying, ensuring that its waterproof performance does not diminish under long-term outdoor use.

▼Structural, multi-dimensional protection

Jumei tent superior performance is based on a steel membrane structure system. A stable “skeleton” is constructed using precision prefabrication of high-strength steel, enabling large-span, column-free spaces and high load-bearing capacity. This ensures the tent structure remains stable in various terrains and climates, effectively avoiding safety hazards caused by structural problems.

▲Hengdian Project – Steel Membrane Structure Design Achieves Large-Span Column-Free Space

The conical roof incorporates aerodynamics, efficiently guiding airflow and reducing wind resistance. Its naturally formed steeply sloping roof allows rain and snow to slide off quickly, reducing the risk of accumulation and seepage. The double-layered membrane roof structure utilizes the principle of air insulation to effectively block heat transfer.

▼Authoritative testing and endorsement

Jumei Tent possesses a complete production and manufacturing industrial chain, implements a standardized production management and quality control system throughout the entire process, has passed the audit of the China Quality Certification Center (CQC), obtained ISO 9001 quality management system certification, and has obtained certifications from authoritative organizations such as CE, SGS, and TUV. It has also obtained nearly 200 patents, including invention, design, and utility model patents.

▲Certified by authoritative institutions, ensuring superior quality

Technological innovation empowers safety without blind spots

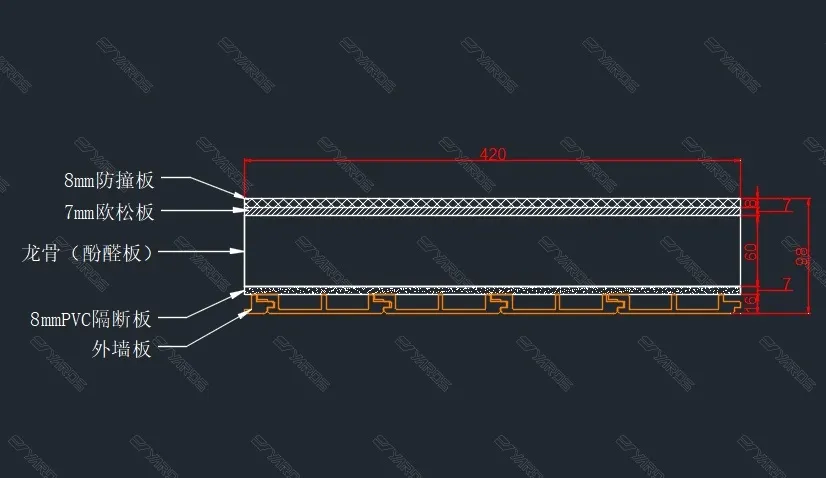

The walls and bathrooms are all constructed using an integrated molding process, systematically prefabricating and redefining outdoor safety and quality standards. The core of the integrated walls uses phenolic boards that meet the national standard Class A fire resistance rating, which are then composited with OSB boards, PVC partition boards, and other materials through a precision process, resulting in excellent flame retardancy and thermal insulation.

▲Innovative Integrated Wall Panel Technology

Standardized pre-installation and integration of water and electricity pipelines are completed in the factory, and walls and bathrooms only need to be quickly assembled on-site. This effectively avoids the risk of sealing damage and leakage caused by wet construction on-site.

▲Integrated prefabricated bathroom

From material selection to process implementation, Jumei prefabricated tents elevate tent construction safety standards to a new level with a design logic of “prevention first, proactive protection.” While pursuing outdoor experience and spatial flexibility, they truly achieve “safety implemented in every detail.”